Tire Test Software

In order for us to run a truly world-class tire testing facility, we have developed a number of internal software tools that maximize our efficiency and the quality of data and models that our customers receive. These tools range from test creation and execution to data processing to TYDEX creation. Right now, we are in the process of commercializing these tools, which means that they will soon be available to various customers, including those from other test facilities, consultancy firms, automotive OEMs, and tire manufacturers.

We have already licensed some of these tools to select customers, and the feedback has been very positive. This interaction has been carried out under the umbrella of our Center for Excellence, a bespoke, year-round consultancy service in which we provide holistic support for the entire toolchain of tire testing, tire modelling, and vehicle simulations. The close relationship we have with such customers has allowed us to gain vital feedback on these software tools, which allows refinements before bringing them to market. A snapshot of the tools in development:

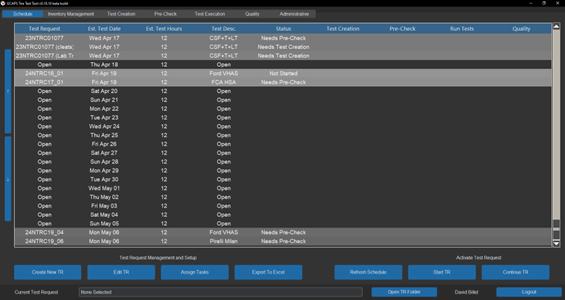

Tire Operations Tool

The Tire Operations Tool is a one-stop shop for end-to-end tire testing. It handles test scheduling, manages tire and wheel inventory, implements quality checks after tests have been completed, and more. It will also feature an intuitive test creation tab which allows end users to quickly create tire tests, overcoming cumbersome restrictions of software which are not intuitive or efficient.

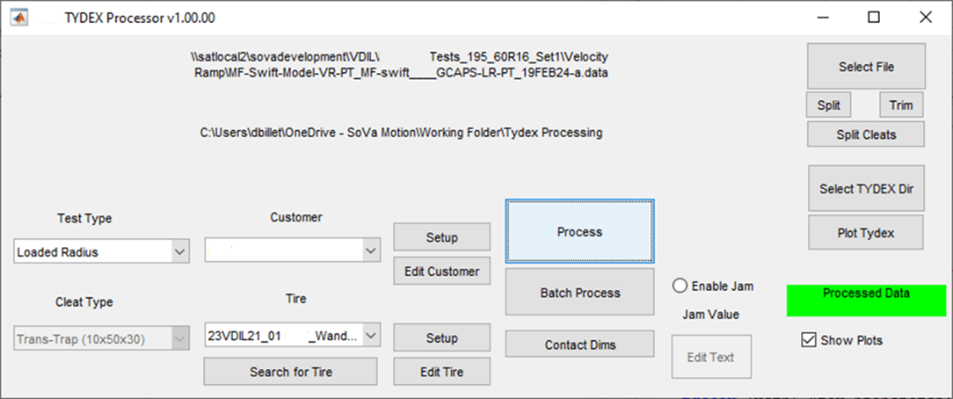

TYDEX processor

The output of tire testing machines is raw data, often in binary format. This needs to be converted into a common file format accepted by all tire model software: TYDEX. Traditionally, end users create data processing tools which are both customer- and tire model-specific. Our TYDEX processor will allow end users to use one tool to create TYDEX files for multiple tire model software vendors (MF-Tyre/MF-Swift, FTire, CDTire, PAC2002, etc.), and will be completely customizable to their own tire test machines. The software will handle not only TYDEX creation but data processing and cropping.

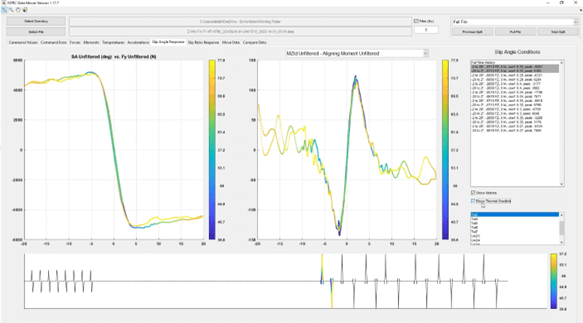

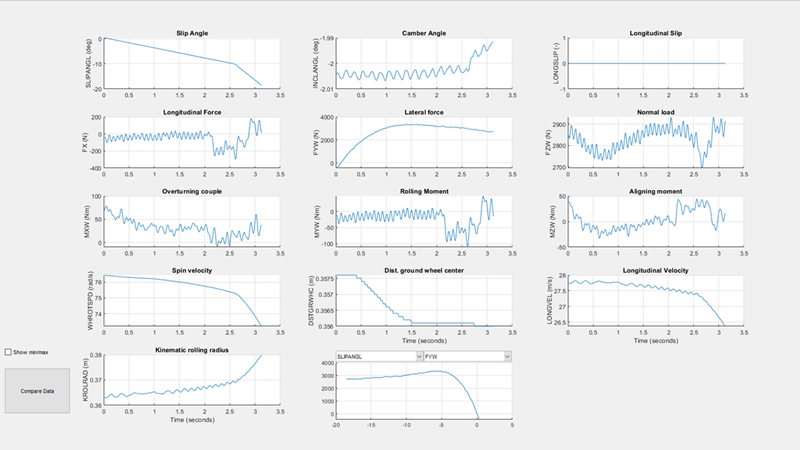

Data Mover

The Data Mover is used as a space to review and inspect data files. We use this internally at GCAPS to check that recorded data are of the highest quality before they are sent to customers. However, we also have customers using this tool to review test data from multiple sources, internally and externally (e.g., from a supplier). In addition to simply inspecting data, the Data Mover calculates several key metrics of high importance to tire modelers, such as cornering, longitudinal slip stiffnesses, and peak force values. There is a degree of customization, too, with users able to create templates of custom-chosen channels to import by default. In addition, the Data Mover creates backups of test data, moves it from one source to another, and allows users to keep their local drives clean, thereby improving operational efficiency.