Dr. Yi Li Recaps the 2024 Tire Society Meeting

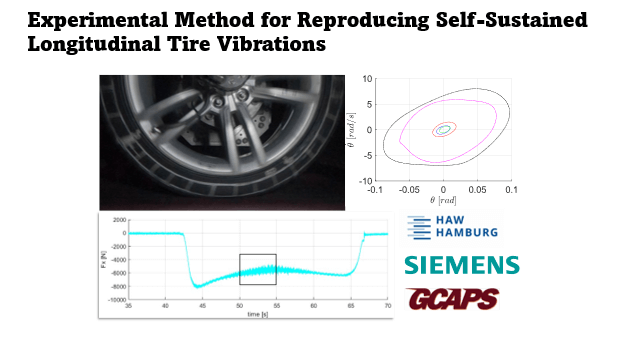

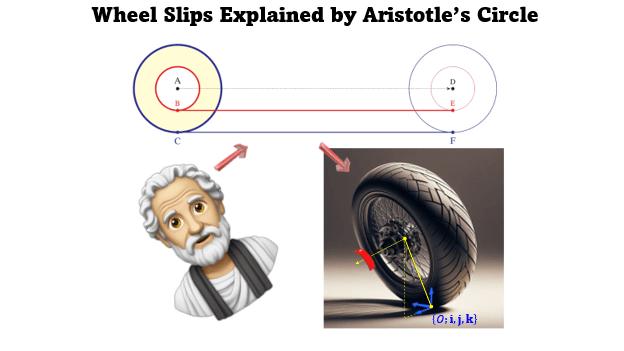

In September of this year, GCAPS Research scientist, Dr. Yi Li, attended the 2024 Tire Society Meeting in Akron, Ohio. At the conference, he presented twice on the topics of “Wheel Slips Explained by Aristotle’s Circle” and “Experimental Methods for Reproducing Self-Sustained Longitudinal Tire Vibrations.” Learn what Li had to say about his time at the conference!

Were any helpful ideas for improving your work relative to either talk brought to your attention?

Of course. During the break, Carlos from WOM Testing Technology approached me for open discussions. We both agreed that the next step is to identify several typical rolling states so that the new definition considerably differs from the traditional definition in terms of resulting forces and moments. Then, I can use these cases to convince people the old definition is insufficient and could lead to problems when dealing with complicated rolling kinematics.

What excites you about the path you are on with your work? How does your work impact the performance for the challenges we face today?

I cherish the opportunity and freedom gained in GCAPS, allowing me to explore my interests. After years of working in the area, I realized that test data is not always ideal. To deeply understand the measurement, you have to know the physics of both the test machine and tire. Then, you can separate the tire response from the overall data involving test machine and tire dynamics. My interest is to gain more insights into tire dynamics from real physical data, which excites me on the current path. Testing and modeling are two powerful tools to help your understanding. By reconciling the measurement and model, the more you could interpret the deviation, the better match you can achieve next time. Interpreting the data requires math models, and good models require high-quality data to calibrate.

The Flat-Trac LTR that GCAPS has is unlike any other tire testing machine. It boasts a bigger load cell and faster speeds than any other tire testing machine available. I would exploit the dynamic capability of the machine to reveal the tire behavior beyond the steady-state regime. The data generated through novel test techniques will benefit modeling and simulation.

Different models serve different purposes in real applications. I use my expertise to choose the right model to satisfy the user’s demands. The right model, in my opinion, does not mean accurate or complex; it means the model is made up of essential components reflecting the dominant mechanics that users demand without bringing in too many trivial factors. I also appreciate fundamental works that can impact vehicle performance in various aspects rather than following the immediate/short-term hot topics.