Asphaltant Open Day

There are complementary advantages and disadvantages to testing tires indoors versus outdoors. In brief, testing indoors is incredibly reliable, repeatable, and tends to be more cost-effective. However, testing on a Flat-Trac utilizes a sandpaper surface, which can create less realistic tire models for certain applications where the frictional performance of the tire is critical (e.g., antilock brake system braking). Conversely, testing outdoors, while more realistic, is typically less reliable and repeatable (owing to weather and surface changes), often more expensive, and usually less capable than indoor testing (e.g., normal load restrictions, braking only).

Many Ph.D. projects have been conducted on this topic, and despite significant progress with various approaches, there is no off-the-shelf solution available for customers today. Over the past few years, GCAPS has been developing an engineered surface that can be mounted to our light truck and racing electric (LTRe) system: Asphaltant. This is an asphalt-like surface, made with real stones/aggregates, which can flex around the drums of the LTRe. After co-developing this surface with motorsports customers, we are now able to offer Flat-Trac testing on Asphaltant to all customers.

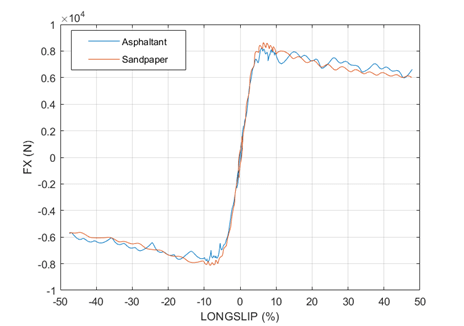

To mark this milestone, we hosted two open days in September, where we invited selected customers to test on Asphaltant free of charge. Customers ranged from motorsports to prominent OEMs to international tire manufacturers. Initial feedback looks promising, with a complete analysis of results to be presented at a conference in 2025. For now, you can see a close-up of the surface and some initial data comparisons between sandpaper and Asphaltant below. The graph shows a higher peak force on sandpaper, with a sharper drop-off—exactly what we expect from differences between sandpaper and asphalt.